Modern manufacturing systems are characterized by an increasingly commonness of cyber-physical systems (CPS), a term referring to production machines which are equipped with sensing, computation and communication capabilities. Realized through microprocessors, sensors and various wired and wireless network interfaces, these systems are capable to provide a continuous, current and comprehensive data stream on the machine and its environment. Moreover, even products themselves are increasingly equipped with these capabilities, resulting an an ever increasing amount of data to be considered in production planning and control (PPC).

This plethora of available data harbors various potentially beneficial information for all aspects of PPC, as well as maintenance and management. However, in order to access such information suitable data processing is required. The high dimension and density of data, combined with an ever higher frequency of data collection complicates the application of traditional statistical methods and optimization approaches due to the subsequently required computation.

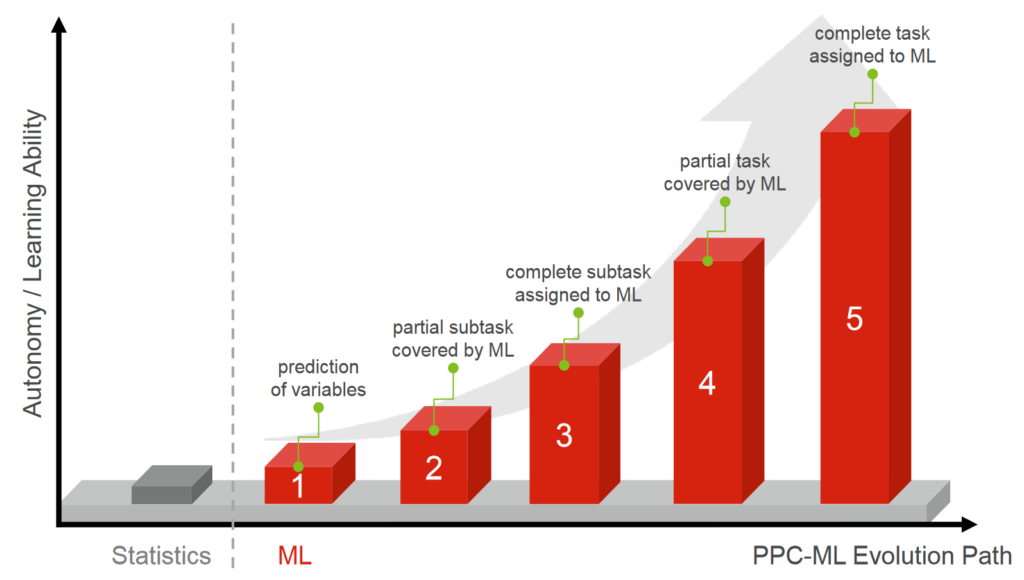

Machine learning can work with large data sets in a relative short amount of time, thus possessing great potential for application in PPC. According to the Aachener PPC model, the entirety of PPC can be divided into various general task, which themselves can consist of numerous subtasks. Similar to the incremental but increasing application of digitization, an increasing Machine Learning maturity in PPC is expected, showcased above.

| PPC-Task | PPC-Subtask | PPC-ML level | |||||

|---|---|---|---|---|---|---|---|

| 1a | 1b | 2 | 3 | 4 | 5 | ||

| Production program planning | Sales planning | 2 | 9 | ||||

| Primary requirements planning | |||||||

| Rough resource planning | |||||||

| Production requirements planning | Determination of gross secondary production requirements | ||||||

| Determination of net secondary production requirements | |||||||

| Procurement type assignment | |||||||

| Lead time scheduling | 4 | 8 | 1 | ||||

| Calculation of capacity needs | |||||||

| Comparison & adjustment of capacities | 4 | ||||||

| In-plant production planning and control | Calculation of batch sizes | 3 | 2 | ||||

| Detailed scheduling | 8 | 15 | 1 | ||||

| Detailed planning of resources | 5 | 11 | 13 | 9 | |||

| Sequencing of orders | 1 | 5 | 6 | ||||

| Availability check | 2 | 3 | |||||

| Release of production orders | 1 | 2 | 2 | ||||

| Order management | Bid processing | ||||||

| Order processing | |||||||

| Order coordination | 1 | 3 | |||||

| Inventory management | Inventory planning | 1 | |||||

| Inventory analysis | |||||||

| Warehouse management | |||||||

| Stock keeping | |||||||

| Batch management | |||||||

| PPC-controlling | Information processing | 1 | |||||

| Deriving measures | |||||||

| Other | Other | 8 | 5 | 2 | |||

| Sum | 22 | 55 | 31 | 32 | |||

In 2022, we conducted a survey on the application of Machine Learning in PPC and its maturity [1]. The results of this study are presented in the table above, showcasing a strong concentration of Machine Learning applications within the task of in-plant production planning and control, where much performance can be gained by accurate and quick prediction. However, while some applications of Machine Learning could be identified for every task according to the Aachener PPC model, at most subtasks were assigned to machine learning application in their respective entirety.

Overall, the application of Machine Learning within PPC is constantly increasing leveraging the vast amount of data now accessible through increasingly common cyber-physical systems and increasing digitization between partners within a supply chain.

References