2025

Oliver Antons; Julia C. Arlinghaus

Manufacturing Network Topologies for Sustainable Production Proceedings Article

In: Mizuyama, Hajime; Morinaga, Eiji; Nonaka, Tomomi; Kaihara, Toshiya; Cieminski, Gregor; Romero, David (Hrsg.): Advances in Production Management Systems. Cyber-Physical-Human Production Systems: Human-AI Collaboration and Beyond, S. 297–310, Springer Nature Switzerland, Cham, 2025, ISBN: 978-3-032-03546-2.

Abstract | Links | BibTeX | Schlagwörter: Manufacturing network topology, Production Planning, Production planning and control, Sustainability

@inproceedings{10.1007/978-3-032-03546-2_20,

title = {Manufacturing Network Topologies for Sustainable Production},

author = {Oliver Antons and Julia C. Arlinghaus},

editor = {Hajime Mizuyama and Eiji Morinaga and Tomomi Nonaka and Toshiya Kaihara and Gregor Cieminski and David Romero},

url = {https://link.springer.com/chapter/10.1007/978-3-032-03546-2_20},

doi = {10.1007/978-3-032-03546-2_20},

isbn = {978-3-032-03546-2},

year = {2025},

date = {2025-08-30},

urldate = {2025-08-30},

booktitle = {Advances in Production Management Systems. Cyber-Physical-Human Production Systems: Human-AI Collaboration and Beyond},

pages = {297\textendash310},

publisher = {Springer Nature Switzerland},

address = {Cham},

abstract = {The linear transformation of finite resources to consumer electronics which are disregarded as waste after ever shorter lifespans is becoming notably problematic from both societal and ecological perspective. Increasing concerns for climate change and resource shortages as well as global supply chain disruptions highlight the deficits of linear economy. The alternative concept of circular economy introduces multiple sustainable strategies to traditional waste management at different points in a typical products lifespan, namely reduce, reuse, recycle, recovery, redesign, and remanufacturing (6R). However, circular economy has seen little adaption in practice. A major obstacle in the implementation of circular practices into production processes lies within the associated costs on the one hand, and the still relatively cheap access to virgin raw materials in large quantities from rather centralized supply systems on the other hand. Sustainable sourcing alternatives are typically characterized by limited local supply due to the corresponding catchment areas of recycling systems. Consequently, circular economy approaches lead to a more decentralized supply networks, increasing logistics costs and questioning established manufacturing topologies. In this article, we develop a minimal mixed-integer linear program in order to compare various spatial manufacturing topologies and supply networks with regard to linear and circular economy concepts. Considering the computational cost for established optimization concepts, we sketch a possible distributed approach to compare different manufacturing topologies and discuss their implications for practice and theory.},

keywords = {Manufacturing network topology, Production Planning, Production planning and control, Sustainability},

pubstate = {published},

tppubtype = {inproceedings}

}

Daniel Cuellar-Usaquén; Marlin W. Ulmer; Oliver Antons; Julia C. Arlinghaus

Dynamic multi-period recycling collection routing with uncertain material quality Artikel

In: OR Spectrum, 2025, ISSN: 1436-6304.

Abstract | Links | BibTeX | Schlagwörter: Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability

@article{Cuellar-Usaqu\'{e}n2025,

title = {Dynamic multi-period recycling collection routing with uncertain material quality},

author = {Daniel Cuellar-Usaqu\'{e}n and Marlin W. Ulmer and Oliver Antons and Julia C. Arlinghaus},

url = {https://www.ms.ovgu.de/Research/Data.html

https://www.ms.ovgu.de/ms_media/Downloads/Data_Dynamic_Multi_Period_Recycling_Collection_Routing-p-604.zip

https://rdcu.be/d9abe

},

doi = {10.1007/s00291-025-00808-z},

issn = {1436-6304},

year = {2025},

date = {2025-02-08},

urldate = {2025-02-08},

journal = {OR Spectrum},

publisher = {Springer Science and Business Media LLC},

abstract = {We consider the problem of collecting and processing waste material. At a production facility, a known amount of inventory is required for production (e.g., paper) for every period. Instead of new material, the facility relies on collected and processed waste material (e.g., paper waste). This material is collected from regional waste collection locations. The amount of waste material per location is uncertain, as is the quality of the collected waste, i.e., the resulting inventory when processing the material. If the inventory is insufficient at the end of a period, costly new material must be bought. Each period, decisions are made about how much waste material to collect from which location and how to route the collection vehicles accordingly. Ideally, inventory is built to hedge against quality uncertainty and to ensure efficient routing operations in future periods. We propose a stochastic lookahead method that samples a set of scenarios and solves a simplified two-stage stochastic program in every period. We show the value of our method for two case studies, one based on real-world data from Sachsen-Anhalt, Germany, and one from the literature with data from the United Kingdom. We further conduct a detailed analysis of our method and the problem characteristics. The results show that our method effectively anticipates all sources of uncertainty, reducing cost significantly compared to benchmark policies. This superior performance is due to appropriate state-dependent supplier selection that considers the percentage of material loss, available material, and routing cost for current and future periods.},

keywords = {Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability},

pubstate = {published},

tppubtype = {article}

}

Anna-Kristin Behnert; Oliver Antons; Lena Prieß; Julia Arlinghaus

Data-Driven Circularity: The Role of Data Spaces in fostering Sustainable Manufacturing Artikel

In: IFAC-PapersOnLine, Bd. 59, Nr. 10, S. 1241-1246, 2025, ISSN: 2405-8963, (11th IFAC Conference on Manufacturing Modelling, Management and Control MIM 2025).

Abstract | Links | BibTeX | Schlagwörter: Circular Economy, Data Space, Sustainability

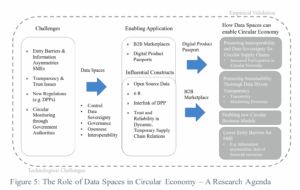

@article{BEHNERT20251241,

title = {Data-Driven Circularity: The Role of Data Spaces in fostering Sustainable Manufacturing},

author = {Anna-Kristin Behnert and Oliver Antons and Lena Prie\ss and Julia Arlinghaus},

url = {https://www.sciencedirect.com/science/article/pii/S240589632500970X},

doi = {https://doi.org/10.1016/j.ifacol.2025.09.209},

issn = {2405-8963},

year = {2025},

date = {2025-01-01},

urldate = {2025-01-01},

journal = {IFAC-PapersOnLine},

volume = {59},

number = {10},

pages = {1241-1246},

abstract = {The transition to a Circular Economy is critical for achieving sustainable manufacturing. However, challenges such as complex supply chains, lack of transparency and stakeholder collaboration are hindering progress. This paper examines the potential of Data Spaces to overcome these challenges and promote sustainable production practices. A systematic review of the literature and abibliometric analysis were conducted to identify key research areas, geographical trends, synergies and gaps in the intersection of Da ta Spaces and Circular Economy. Subsequently, propositions were derived regarding the potential of Data Spaces to foster Circular Economy. By integrating Digital Product Pass ports and federated B2B marketplaces, Da ta Spaces facilitate recycling, repair and reuse processes, while simultaneously reducing the barrier to entry for small and medium-sized enterprises. The findings underscore the transformative role of Data Spaces in operation a lizingcircular principles. A research agenda is proposed to guide future empirical and theoretical studies in this domain.},

note = {11th IFAC Conference on Manufacturing Modelling, Management and Control MIM 2025},

keywords = {Circular Economy, Data Space, Sustainability},

pubstate = {published},

tppubtype = {article}

}

2024

Anna-Kristin Behnert; Oliver Antons; Julia Arlinghaus

Exploring the Challenges of Circular Economy Adoption: A Supply Chain Perspective Artikel

In: IFAC-PapersOnLine, Bd. 58, Nr. 19, S. 211-216, 2024, ISSN: 2405-8963, (18th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2024).

Abstract | Links | BibTeX | Schlagwörter: Cause-And-Effect Relationships, Circular Economy, Circular Supply Chain, Supply Chain Management, Sustainability

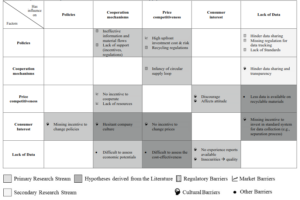

@article{BEHNERT2024211,

title = {Exploring the Challenges of Circular Economy Adoption: A Supply Chain Perspective},

author = {Anna-Kristin Behnert and Oliver Antons and Julia Arlinghaus},

url = {https://www.sciencedirect.com/science/article/pii/S2405896324015829},

doi = {https://doi.org/10.1016/j.ifacol.2024.09.168},

issn = {2405-8963},

year = {2024},

date = {2024-01-01},

urldate = {2024-01-01},

journal = {IFAC-PapersOnLine},

volume = {58},

number = {19},

pages = {211-216},

abstract = {The prevailing linear economic structure and our complex global supply chains are reaching their tangible limits, as evidenced by the impact of current crises such as energy scarcity. A shift from a linear to a Circular Economy is necessary to meet the urgent environmental and economic challenges. This paper aims to address a significant gap in the literature by utilizing a structured literature review and the Supply Chain Operation Reference (SCOR) model. Rather than focusing on specific contexts or industries, this paper aims to examine the intercorrelation and interdependencies between the barriers from a supply chain perspective. Therefore, the diverse conceptual background of the Circular Economy and the complexity of its implementation due to the interconnectedness of barriers that span regulatory, cultural, market, and technological aspects are analyzed. The interdependence of barriers in the different supply chain stages is highlighted in a qualitative and explorative research approach. The key findings reveal that a successful supply chain management strategy that integrates Circular Economy principles along the whole supply chain is crucial for successfully transitioning from a linear to a Circular Economy. We identify necessary lines of future research to facilitate the successful transition and overcome the current barriers along the supply chain.},

note = {18th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2024},

keywords = {Cause-And-Effect Relationships, Circular Economy, Circular Supply Chain, Supply Chain Management, Sustainability},

pubstate = {published},

tppubtype = {article}

}

2023

Oliver Antons; Tobias Benecke; Sanaz Mostaghim; Julia C. Arlinghaus

Sustainability in Chemical Production–Multi-Objective Distributed Control Buchabschnitt

In: New Trends in Intelligent Software Methodologies, Tools and Techniques, S. 211–219, IOS Press, 2023.

Abstract | Links | BibTeX | Schlagwörter: Chemical industry, Circular Economy, Distributed control, Optimization, Sustainability

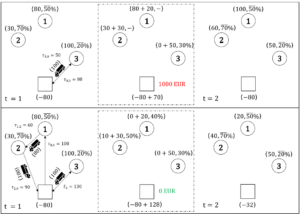

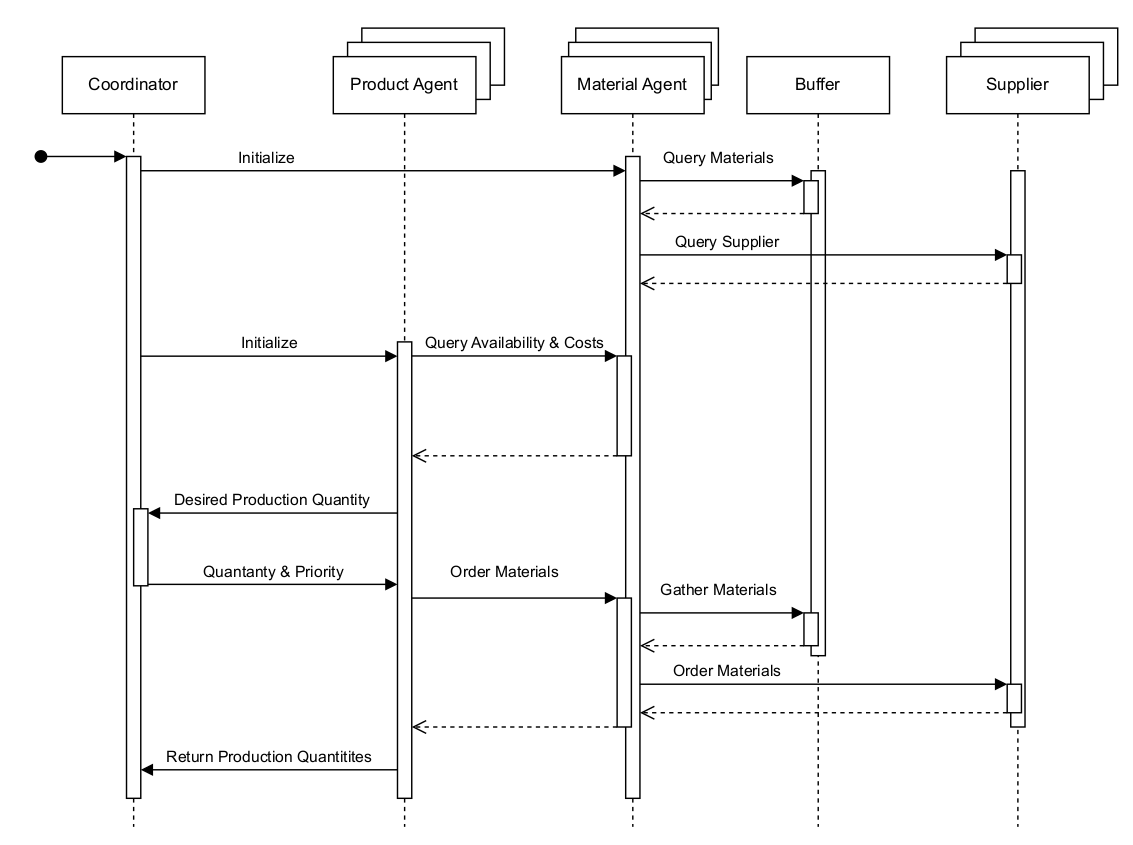

@incollection{antons2023sustainability,

title = {Sustainability in Chemical Production\textendashMulti-Objective Distributed Control},

author = {Oliver Antons and Tobias Benecke and Sanaz Mostaghim and Julia C. Arlinghaus},

doi = {10.3233/FAIA230236},

year = {2023},

date = {2023-01-01},

urldate = {2023-01-01},

booktitle = {New Trends in Intelligent Software Methodologies, Tools and Techniques},

pages = {211\textendash219},

publisher = {IOS Press},

abstract = {Chemical industry provides a multitude of intermediaries and final products essential to society, ranging from fertilizers and plastics to sophisticated pharmaceuticals. The underlying production processes are typically linear, utilizing finite resources in an unsustainable manner and creating unnecessary waste over a products lifetime. While a shift towards sustainability and circular economy is desired, the current market and political framework lead to conflicting objectives ranging from sustainability to profit maximization. In this article, we build upon a first minimal multi-objective MILP model and extend thereupon, reducing the overall level of required abstraction compared to the first model. Thereafter, we present a multi-agent based distributed optimization approach for a sequence of the extended MILP formulation.},

keywords = {Chemical industry, Circular Economy, Distributed control, Optimization, Sustainability},

pubstate = {published},

tppubtype = {incollection}

}

2019

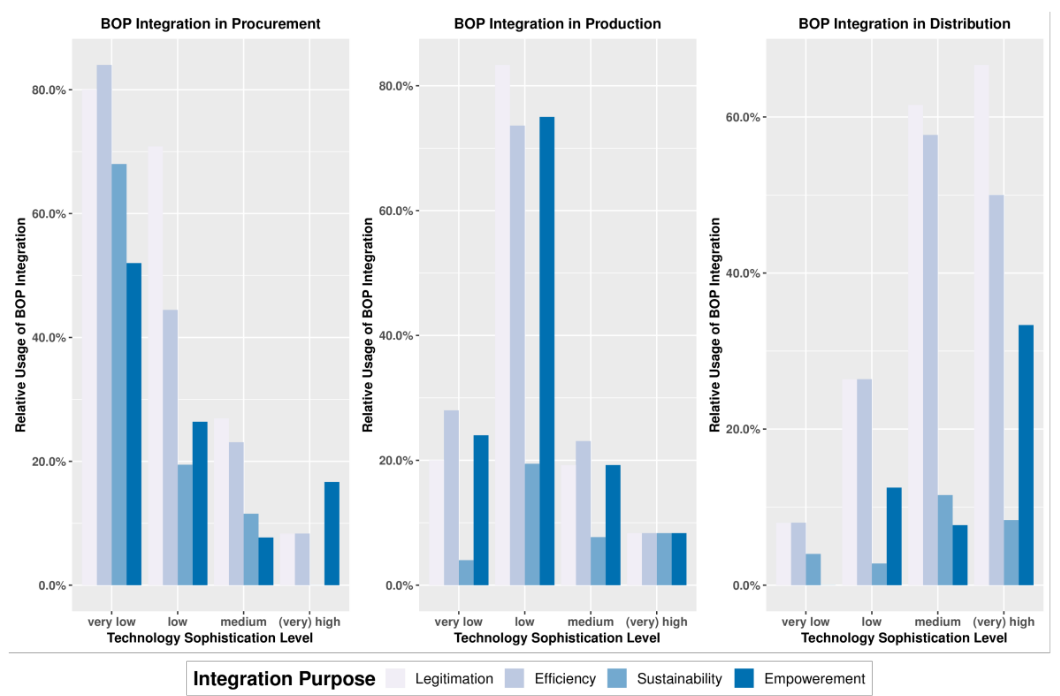

Stephanie Knizkov; Oliver Antons; Julia C. Bendul

Designing Inclusive Supply Chains for Sustainability: Empirical Insights from the Bottom of the Global Economic Pyramid Proceedings Article

In: EurOMA19, 2019.

Abstract | BibTeX | Schlagwörter: Base of the Pyramid, Co-creation, Sustainability, Sustainable Development

@inproceedings{Knizkov-2019,

title = {Designing Inclusive Supply Chains for Sustainability: Empirical Insights from the Bottom of the Global Economic Pyramid},

author = {Stephanie Knizkov and Oliver Antons and Julia C. Bendul},

year = {2019},

date = {2019-01-01},

urldate = {2019-01-01},

booktitle = {EurOMA19},

abstract = {Integration of the population at the Bottom of the Pyramid (BOP) within company operations was identified as pivotal for realizing both value for companies operating in these challenging markets, as well as for harnessing the full potential of the BOP proposition in fostering value for individuals living in them. However, research on the topic remains predominantly simplistic, with nuanced and empiric based argumentation relatively scarce. In this paper we address this gap and provide a clear overview of how companies integrate BOP individuals in the different stages of their supply-chain, and how this integration facilitates different levels of sustainability depth.},

keywords = {Base of the Pyramid, Co-creation, Sustainability, Sustainable Development},

pubstate = {published},

tppubtype = {inproceedings}

}