2024

Luca Janecki; Oliver Antons; Daniel Reh; Julia C. Arlinghaus

Comparing Digital Twins and Virtual Engineering in Buyer Supplier Relationships for Complex Production Facilities Proceedings Article

In: Thürer, Matthias; Riedel, Ralph; Cieminski, Gregor; Romero, David (Hrsg.): Advances in Production Management Systems. Production Management Systems for Volatile, Uncertain, Complex, and Ambiguous Environments, S. 180–193, Springer Nature Switzerland, Cham, 2024, ISBN: 978-3-031-71645-4.

Abstract | Links | BibTeX | Schlagwörter: Buyer-Supplier Relationship, Digital Twin, Production, Virtual Engineering

@inproceedings{10.1007/978-3-031-71645-4_13,

title = {Comparing Digital Twins and Virtual Engineering in Buyer Supplier Relationships for Complex Production Facilities},

author = {Luca Janecki and Oliver Antons and Daniel Reh and Julia C. Arlinghaus},

editor = {Matthias Th\"{u}rer and Ralph Riedel and Gregor Cieminski and David Romero},

url = {https://link.springer.com/chapter/10.1007/978-3-031-71645-4_13},

doi = {10.1007/978-3-031-71645-4_13},

isbn = {978-3-031-71645-4},

year = {2024},

date = {2024-01-01},

urldate = {2024-01-01},

booktitle = {Advances in Production Management Systems. Production Management Systems for Volatile, Uncertain, Complex, and Ambiguous Environments},

pages = {180\textendash193},

publisher = {Springer Nature Switzerland},

address = {Cham},

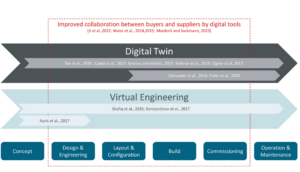

abstract = {In today's highly competitive and interconnected global marketplace, the effective management of buyer-supplier relationships is essential for organizations seeking to stay ahead. With the rise of complex production facilities, ensuring product quality and optimizing communication between buyers and suppliers presents an escalating challenge. This complexity is further compounded by the integration of Digital Twins and Virtual Engineering, requiring innovative solutions to navigate the intricacies of modern supply chain dynamics. This article explores the role of Digital Twins and Virtual Engineering as a strategic approach to enhance buyer-supplier relationship management within the context of complex production facilities using insights from the Principal Agent Theory. Based on a systematic literature review, we explore current approaches to the use of virtual engineering and digital twins to overcome existing tensions from principal-agent theory.},

keywords = {Buyer-Supplier Relationship, Digital Twin, Production, Virtual Engineering},

pubstate = {published},

tppubtype = {inproceedings}

}

2022

Oliver Antons; Julia C. Arlinghaus

In: IEEE Journal of Emerging and Selected Topics in Industrial Electronics, Bd. 3, Nr. 1, S. 31-38, 2022.

Abstract | Links | BibTeX | Schlagwörter: Autonomy & Decision-making Authority, Complexity Theory, Decentralized Control, Job-shop scheduling, Manufacturing, Optimization, Production

@article{antons2021ieee,

title = {A Manufacturing Scheduling Complexity Framework and Agent-Based Comparison of Centralized and Distributed Control Approaches},

author = {Oliver Antons and Julia C. Arlinghaus},

url = {https://doi.org/10.1109/JESTIE.2021.3100272},

doi = {10.1109/JESTIE.2021.3100272},

year = {2022},

date = {2022-01-01},

urldate = {2022-01-01},

journal = {IEEE Journal of Emerging and Selected Topics in Industrial Electronics},

volume = {3},

number = {1},

pages = {31-38},

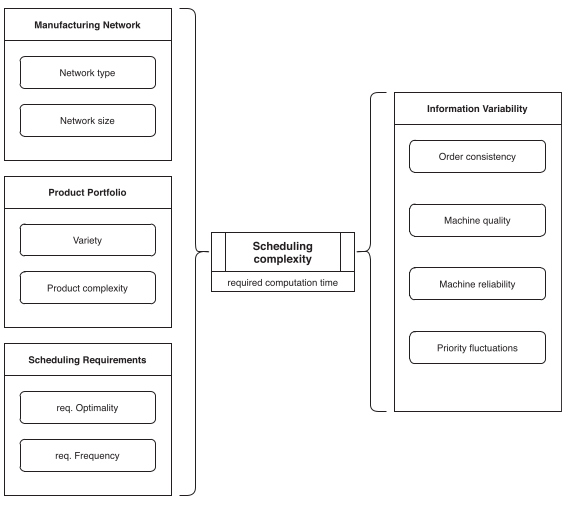

abstract = {Centralized approaches are often employed to control manufacturing networks in practice. The introduction of industrial cyber-physical systems driven by advances in microcontroller, sensor, and networking technologies is providing distributed control systems with the technical requirements needed to mitigate the drawbacks of centralized control, such as long optimization times that result in long planning horizons and inflexibility. While such distributed control approaches respond to the growing challenges faced by industry in terms of flexibility, resilience, and lot sizes, the inherent myopia of autonomous agents may discourage practical application. In this article, we develop a scheduling complexity framework derived from the literature, which allows researchers and prationers alike to evaluate the suitability of both centralized and distributed control approaches for manufacturing planning and control. This framework utilizes quantifiable environment variables, which influence we study by means of a multiagent discrete event simulation.},

keywords = {Autonomy \& Decision-making Authority, Complexity Theory, Decentralized Control, Job-shop scheduling, Manufacturing, Optimization, Production},

pubstate = {published},

tppubtype = {article}

}