2025

Oliver Antons; Julia C. Arlinghaus

Manufacturing Network Topologies for Sustainable Production Proceedings Article

In: Mizuyama, Hajime; Morinaga, Eiji; Nonaka, Tomomi; Kaihara, Toshiya; Cieminski, Gregor; Romero, David (Ed.): Advances in Production Management Systems. Cyber-Physical-Human Production Systems: Human-AI Collaboration and Beyond, pp. 297–310, Springer Nature Switzerland, Cham, 2025, ISBN: 978-3-032-03546-2.

Abstract | Links | BibTeX | Tags: Manufacturing network topology, Production Planning, Production planning and control, Sustainability

@inproceedings{10.1007/978-3-032-03546-2_20,

title = {Manufacturing Network Topologies for Sustainable Production},

author = {Oliver Antons and Julia C. Arlinghaus},

editor = {Hajime Mizuyama and Eiji Morinaga and Tomomi Nonaka and Toshiya Kaihara and Gregor Cieminski and David Romero},

url = {https://link.springer.com/chapter/10.1007/978-3-032-03546-2_20},

doi = {10.1007/978-3-032-03546-2_20},

isbn = {978-3-032-03546-2},

year = {2025},

date = {2025-08-30},

urldate = {2025-08-30},

booktitle = {Advances in Production Management Systems. Cyber-Physical-Human Production Systems: Human-AI Collaboration and Beyond},

pages = {297\textendash310},

publisher = {Springer Nature Switzerland},

address = {Cham},

abstract = {The linear transformation of finite resources to consumer electronics which are disregarded as waste after ever shorter lifespans is becoming notably problematic from both societal and ecological perspective. Increasing concerns for climate change and resource shortages as well as global supply chain disruptions highlight the deficits of linear economy. The alternative concept of circular economy introduces multiple sustainable strategies to traditional waste management at different points in a typical products lifespan, namely reduce, reuse, recycle, recovery, redesign, and remanufacturing (6R). However, circular economy has seen little adaption in practice. A major obstacle in the implementation of circular practices into production processes lies within the associated costs on the one hand, and the still relatively cheap access to virgin raw materials in large quantities from rather centralized supply systems on the other hand. Sustainable sourcing alternatives are typically characterized by limited local supply due to the corresponding catchment areas of recycling systems. Consequently, circular economy approaches lead to a more decentralized supply networks, increasing logistics costs and questioning established manufacturing topologies. In this article, we develop a minimal mixed-integer linear program in order to compare various spatial manufacturing topologies and supply networks with regard to linear and circular economy concepts. Considering the computational cost for established optimization concepts, we sketch a possible distributed approach to compare different manufacturing topologies and discuss their implications for practice and theory.},

keywords = {Manufacturing network topology, Production Planning, Production planning and control, Sustainability},

pubstate = {published},

tppubtype = {inproceedings}

}

2023

Oliver Antons; Julia C. Arlinghaus

Designing distributed decision-making authorities for smart factories – understanding the role of manufacturing network architecture Journal Article

In: International Journal of Production Research, vol. 0, no. 0, pp. 1-19, 2023.

Abstract | Links | BibTeX | Tags: Autonomous production control, Autonomy & Decision-making Authority, Centralized control, Decision-making authority, Distributed control, Manufacturing network topology, Production planning and control

@article{doi:10.1080/00207543.2023.2217285,

title = {Designing distributed decision-making authorities for smart factories \textendash understanding the role of manufacturing network architecture},

author = {Oliver Antons and Julia C. Arlinghaus},

url = {https://doi.org/10.1080/00207543.2023.2217285},

doi = {10.1080/00207543.2023.2217285},

year = {2023},

date = {2023-01-01},

urldate = {2023-01-01},

journal = {International Journal of Production Research},

volume = {0},

number = {0},

pages = {1-19},

publisher = {Taylor \& Francis},

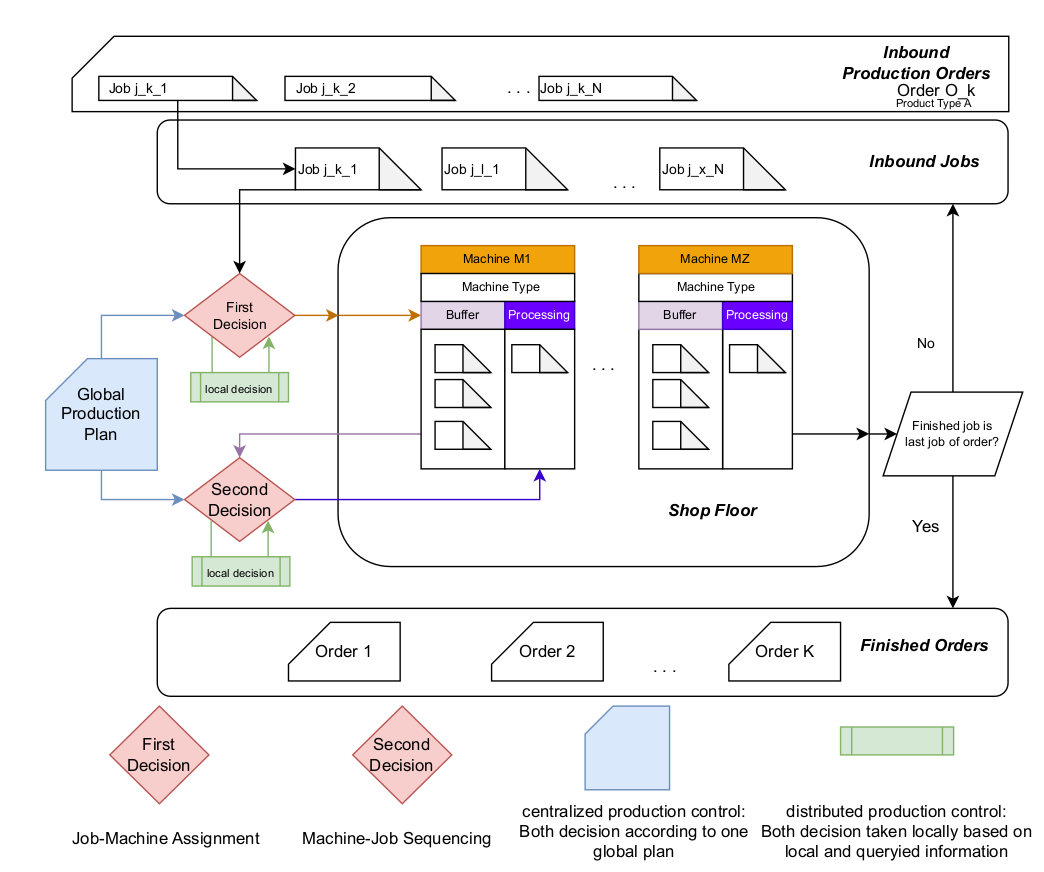

abstract = {The availability of cyber-physical systems (CPS) in modern manufacturing networks provides a multitude of interesting opportunities from a manufacturing control perspective. Providing sensors, data gathering, local computation and communication capabilities modern CPS fulfil the technical requirements to act completely autonomously in a manufacturing network. While the distribution of decision-making authority to autonomous entities is feasible given such requirements, practice often sees the monopolisation of decision-making authority for centralised control. However, distributed production control approaches might be better suited given current manufacturing challenges, ranging from unreliable supply chains over highly volatile markets, to the demand for increasingly efficient and highly customisable production. In this article, we extend an existing scheduling complexity framework which enables practitioners and researchers alike to assess the aptitude of given manufacturing networks for both centralised and distributed control. In particular, we study the influence of a manufacturing network's topology ranging from assembly line to job shops on the aforementioned aptitude, with total production costs as objective.

We utilise a multi-agent-based discrete-event simulation comparing an MILP-based centralised control approach and an autonomy based distributed control approach with weighted costs as decision function to evaluate this framework. Our results provide novel insights regarding the influence of manufacturing network topologies on the scheduling complexity of manufacturing networks.},

keywords = {Autonomous production control, Autonomy \& Decision-making Authority, Centralized control, Decision-making authority, Distributed control, Manufacturing network topology, Production planning and control},

pubstate = {published},

tppubtype = {article}

}

We utilise a multi-agent-based discrete-event simulation comparing an MILP-based centralised control approach and an autonomy based distributed control approach with weighted costs as decision function to evaluate this framework. Our results provide novel insights regarding the influence of manufacturing network topologies on the scheduling complexity of manufacturing networks.