2025

Daniel Cuellar-Usaquén; Marlin W. Ulmer; Oliver Antons; Julia C. Arlinghaus

Dynamic multi-period recycling collection routing with uncertain material quality Journal Article

In: OR Spectrum, 2025, ISSN: 1436-6304.

Abstract | Links | BibTeX | Tags: Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability

@article{Cuellar-Usaqu\'{e}n2025,

title = {Dynamic multi-period recycling collection routing with uncertain material quality},

author = {Daniel Cuellar-Usaqu\'{e}n and Marlin W. Ulmer and Oliver Antons and Julia C. Arlinghaus},

url = {https://www.ms.ovgu.de/Research/Data.html

https://www.ms.ovgu.de/ms_media/Downloads/Data_Dynamic_Multi_Period_Recycling_Collection_Routing-p-604.zip

https://rdcu.be/d9abe

},

doi = {10.1007/s00291-025-00808-z},

issn = {1436-6304},

year = {2025},

date = {2025-02-08},

urldate = {2025-02-08},

journal = {OR Spectrum},

publisher = {Springer Science and Business Media LLC},

abstract = {We consider the problem of collecting and processing waste material. At a production facility, a known amount of inventory is required for production (e.g., paper) for every period. Instead of new material, the facility relies on collected and processed waste material (e.g., paper waste). This material is collected from regional waste collection locations. The amount of waste material per location is uncertain, as is the quality of the collected waste, i.e., the resulting inventory when processing the material. If the inventory is insufficient at the end of a period, costly new material must be bought. Each period, decisions are made about how much waste material to collect from which location and how to route the collection vehicles accordingly. Ideally, inventory is built to hedge against quality uncertainty and to ensure efficient routing operations in future periods. We propose a stochastic lookahead method that samples a set of scenarios and solves a simplified two-stage stochastic program in every period. We show the value of our method for two case studies, one based on real-world data from Sachsen-Anhalt, Germany, and one from the literature with data from the United Kingdom. We further conduct a detailed analysis of our method and the problem characteristics. The results show that our method effectively anticipates all sources of uncertainty, reducing cost significantly compared to benchmark policies. This superior performance is due to appropriate state-dependent supplier selection that considers the percentage of material loss, available material, and routing cost for current and future periods.},

keywords = {Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability},

pubstate = {published},

tppubtype = {article}

}

2020

Oliver Antons; Julia C. Arlinghaus

Modelling Autonomous Production Control: A Guide to Select the Most Suitable Modelling Approach Proceedings Article

In: International Conference on Dynamics in Logistics, pp. 245–253, Springer 2020.

Abstract | Links | BibTeX | Tags: Autonomous production control, Autonomy & Decision-making Authority, Discrete-event simulation, Linear programming, Minimal models, Production planning and control

@inproceedings{antons2020modelling,

title = {Modelling Autonomous Production Control: A Guide to Select the Most Suitable Modelling Approach},

author = {Oliver Antons and Julia C. Arlinghaus},

url = {https://link.springer.com/chapter/10.1007/978-3-030-44783-0_24},

doi = {10.1007/978-3-030-44783-0_24},

year = {2020},

date = {2020-01-01},

urldate = {2020-01-01},

booktitle = {International Conference on Dynamics in Logistics},

pages = {245--253},

organization = {Springer},

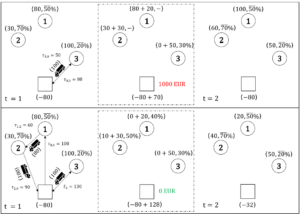

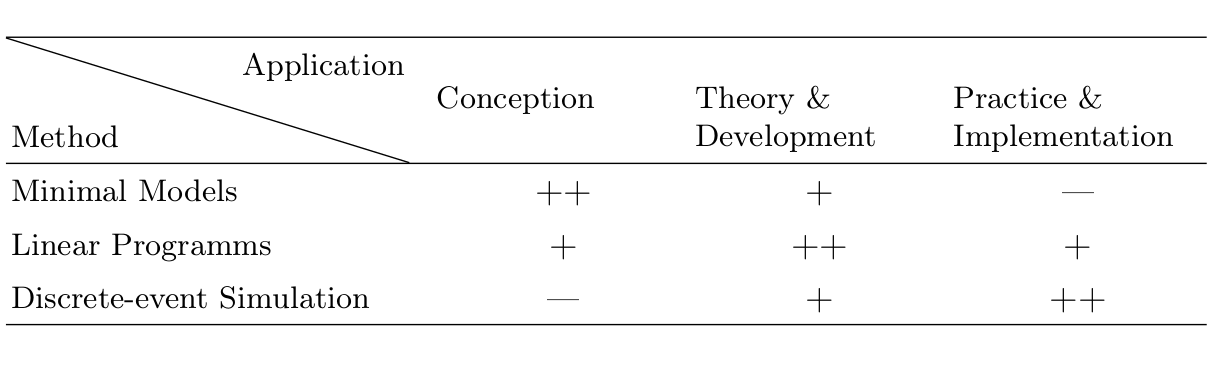

abstract = {This paper studies and compares Minimal Models, Linear Programming and Discrete-event Simulation as approaches to model Production Planning and Control with regard to their ability to include the concept of autonomous control. After a brief explanation of autonomous control in production planning, the three aforementioned concepts are introduced in detail. We derive their benefits and drawbacks for different scenarios, and subsequently give advice when to deploy each method, applicable for researchers and practioners alike.},

keywords = {Autonomous production control, Autonomy \& Decision-making Authority, Discrete-event simulation, Linear programming, Minimal models, Production planning and control},

pubstate = {published},

tppubtype = {inproceedings}

}