2025

Daniel Cuellar-Usaquén; Marlin W. Ulmer; Oliver Antons; Julia C. Arlinghaus

Dynamic multi-period recycling collection routing with uncertain material quality Journal Article

In: OR Spectrum, 2025, ISSN: 1436-6304.

Abstract | Links | BibTeX | Tags: Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability

@article{Cuellar-Usaqu\'{e}n2025,

title = {Dynamic multi-period recycling collection routing with uncertain material quality},

author = {Daniel Cuellar-Usaqu\'{e}n and Marlin W. Ulmer and Oliver Antons and Julia C. Arlinghaus},

url = {https://www.ms.ovgu.de/Research/Data.html

https://www.ms.ovgu.de/ms_media/Downloads/Data_Dynamic_Multi_Period_Recycling_Collection_Routing-p-604.zip

https://rdcu.be/d9abe

},

doi = {10.1007/s00291-025-00808-z},

issn = {1436-6304},

year = {2025},

date = {2025-02-08},

urldate = {2025-02-08},

journal = {OR Spectrum},

publisher = {Springer Science and Business Media LLC},

abstract = {We consider the problem of collecting and processing waste material. At a production facility, a known amount of inventory is required for production (e.g., paper) for every period. Instead of new material, the facility relies on collected and processed waste material (e.g., paper waste). This material is collected from regional waste collection locations. The amount of waste material per location is uncertain, as is the quality of the collected waste, i.e., the resulting inventory when processing the material. If the inventory is insufficient at the end of a period, costly new material must be bought. Each period, decisions are made about how much waste material to collect from which location and how to route the collection vehicles accordingly. Ideally, inventory is built to hedge against quality uncertainty and to ensure efficient routing operations in future periods. We propose a stochastic lookahead method that samples a set of scenarios and solves a simplified two-stage stochastic program in every period. We show the value of our method for two case studies, one based on real-world data from Sachsen-Anhalt, Germany, and one from the literature with data from the United Kingdom. We further conduct a detailed analysis of our method and the problem characteristics. The results show that our method effectively anticipates all sources of uncertainty, reducing cost significantly compared to benchmark policies. This superior performance is due to appropriate state-dependent supplier selection that considers the percentage of material loss, available material, and routing cost for current and future periods.},

keywords = {Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability},

pubstate = {published},

tppubtype = {article}

}

Tobias Bein; Oliver Antons; Julia C. Arlinghaus

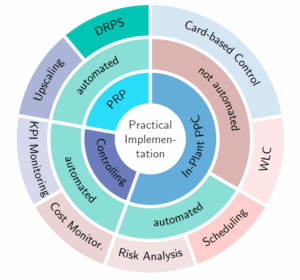

Which PPC-Methods are implemented in Industry? - Yet another Review Journal Article

In: IFAC-PapersOnLine, vol. 59, no. 10, pp. 1005-1010, 2025, ISSN: 2405-8963, (11th IFAC Conference on Manufacturing Modelling, Management and Control MIM 2025).

Abstract | Links | BibTeX | Tags: Control, Decision-making, decision-support systems, literature review, Production planning and control, research-practice gap, theory-practice gap

@article{BEIN20251005,

title = {Which PPC-Methods are implemented in Industry? - Yet another Review},

author = {Tobias Bein and Oliver Antons and Julia C. Arlinghaus},

url = {https://www.sciencedirect.com/science/article/pii/S2405896325009310},

doi = {https://doi.org/10.1016/j.ifacol.2025.09.170},

issn = {2405-8963},

year = {2025},

date = {2025-01-01},

urldate = {2025-01-01},

journal = {IFAC-PapersOnLine},

volume = {59},

number = {10},

pages = {1005-1010},

abstract = {This paper addresses the theory-practice gap in production planning and control (PPC), which describes the degree of applicability of academic research. We will measure this gap based on the reported application of academic research in industry. Therefore, this paper analyzes the current challenges that companies face in the area of PPC by reviewing empirical studies and relevant literature. We use our findings to draw conclusions about topics that are particularly helpful for the practical implementation of PPC methods and systems in industry. In addition, a literature analysis is carried out to provide a current overview on applied research. We show that applied research is still a term used in diverse settings and scenarios, ranging from purely theoretical works to practical implementations. Furthermore, the identified implementation studies are closely reviewed by comparing them to the analyzed topics currently of interest to practitioners. The results indicate that authors report on aspects of transparency as well as stakeholder-interaction, with the former being more prominently depicted.},

note = {11th IFAC Conference on Manufacturing Modelling, Management and Control MIM 2025},

keywords = {Control, Decision-making, decision-support systems, literature review, Production planning and control, research-practice gap, theory-practice gap},

pubstate = {published},

tppubtype = {article}

}

2021

Oliver Antons; Julia C. Arlinghaus

Adaptive self-learning distributed and centralized control approaches for smart factories Proceedings Article

In: pp. 1577-1582, 2021, ISSN: 2212-8271, (54th CIRP CMS 2021 - Towards Digitalized Manufacturing 4.0).

Abstract | Links | BibTeX | Tags: Autonomy, Autonomy & Decision-making Authority, Cyber-physical system, Data analytics, Decision-making, Discrete-event simulation, Distributed control, Industry 4.0, Multi-agent system, Self-learning, Smart factory

@inproceedings{ANTONS20211577,

title = {Adaptive self-learning distributed and centralized control approaches for smart factories},

author = {Oliver Antons and Julia C. Arlinghaus},

url = {https://www.sciencedirect.com/science/article/pii/S2212827121011641},

doi = {https://doi.org/10.1016/j.procir.2021.11.266},

issn = {2212-8271},

year = {2021},

date = {2021-01-01},

urldate = {2021-01-01},

journal = {Procedia CIRP},

volume = {104},

pages = {1577-1582},

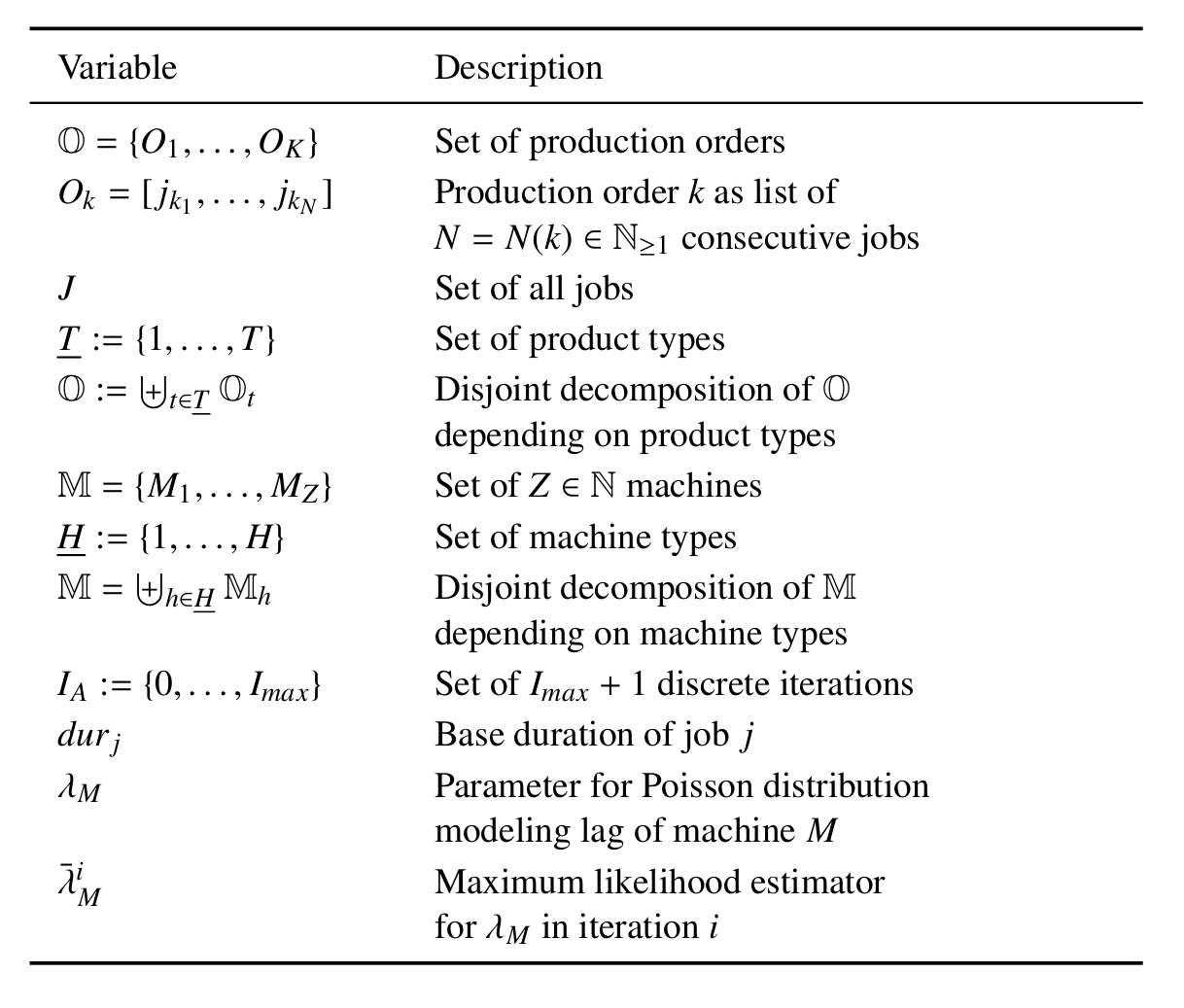

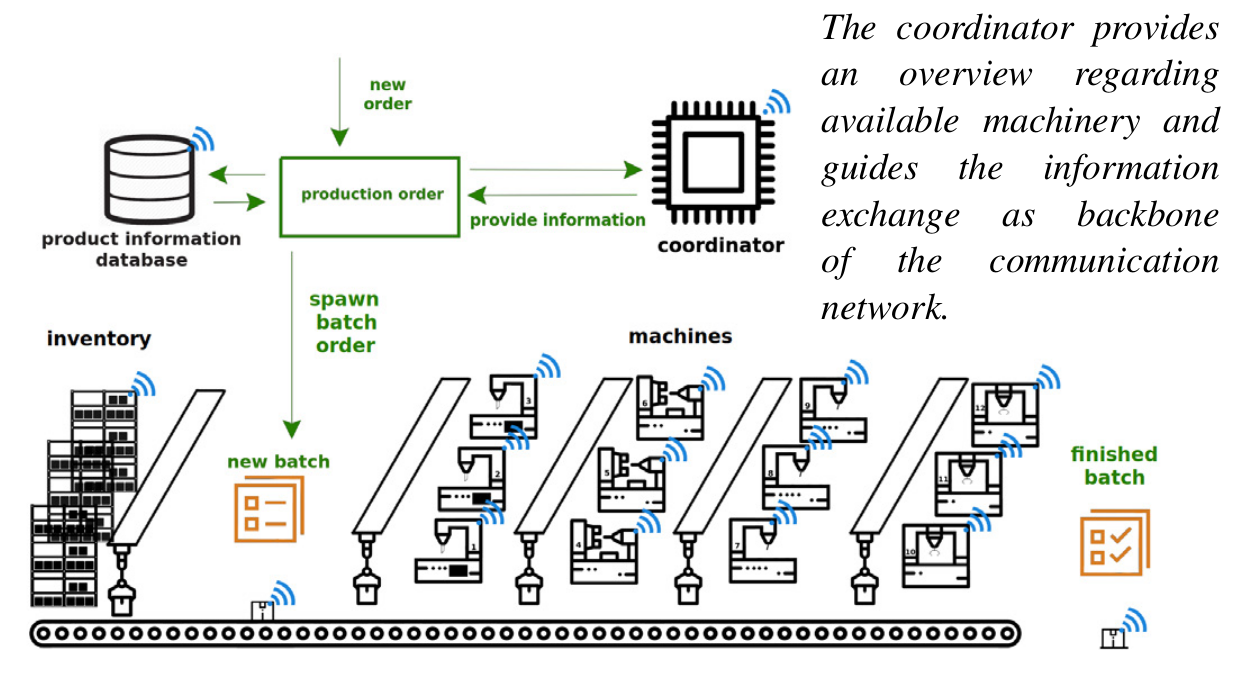

abstract = {The increasing application of cyber-physical systems creates a manufacturing environment in which the technical requirements for distributed control approaches, self-learning systems and analytics of previously untapped data are given. While distributed control approaches are capable to evaluate this information locally and react immediately, centralized approaches react inertly to analyzed machine performance data. In this paper, we study the performance and ability to address the ever increasing challenges in industry of both types of control approaches within an established multi-agent based discrete event simulation.},

note = {54th CIRP CMS 2021 - Towards Digitalized Manufacturing 4.0},

keywords = {Autonomy, Autonomy \& Decision-making Authority, Cyber-physical system, Data analytics, Decision-making, Discrete-event simulation, Distributed control, Industry 4.0, Multi-agent system, Self-learning, Smart factory},

pubstate = {published},

tppubtype = {inproceedings}

}

2020

Oliver Antons; Julia C. Arlinghaus

Designing decision-making authorities for smart factories Proceedings Article

In: pp. 316–322, Elsevier, 2020.

Abstract | Links | BibTeX | Tags: Autonomy, Autonomy & Decision-making Authority, Cyber-physical system, Decision-making, Discrete-event simulation, Distributed control, Industry 4.0, Intelligent Product, Multi-agent system, Smart factory

@inproceedings{antons2020designing,

title = {Designing decision-making authorities for smart factories},

author = {Oliver Antons and Julia C. Arlinghaus},

url = {https://www.sciencedirect.com/science/article/pii/S2212827120306120},

doi = {10.1016/j.procir.2020.04.047},

year = {2020},

date = {2020-01-01},

urldate = {2020-01-01},

journal = {Procedia CIRP},

volume = {93},

pages = {316--322},

publisher = {Elsevier},

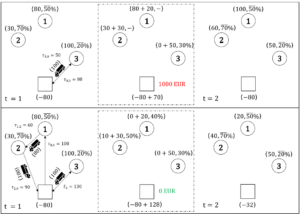

abstract = {Smart factories are an appealing vision, addressing ever increasing challenges in industry. Driven by advances in microcontroller, sensor and networking technologies, all entities, such as machines, products, load carriers, within a smart factory could become intelligent and able to assess their own situation and to attain their own goals successfully. However, local decision may exacerbate achieving global logistics performance due to the entities intrinsic selfishness. In this paper, we explore the trade-off between local decision-making and global performance management and derive first guidelines for the situation-specific design of a distributed control authority for smart factories.},

keywords = {Autonomy, Autonomy \& Decision-making Authority, Cyber-physical system, Decision-making, Discrete-event simulation, Distributed control, Industry 4.0, Intelligent Product, Multi-agent system, Smart factory},

pubstate = {published},

tppubtype = {inproceedings}

}