2025

Daniel Cuellar-Usaquén; Marlin W. Ulmer; Oliver Antons; Julia C. Arlinghaus

Dynamic multi-period recycling collection routing with uncertain material quality Journal Article

In: OR Spectrum, 2025, ISSN: 1436-6304.

Abstract | Links | BibTeX | Tags: Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability

@article{Cuellar-Usaqu\'{e}n2025,

title = {Dynamic multi-period recycling collection routing with uncertain material quality},

author = {Daniel Cuellar-Usaqu\'{e}n and Marlin W. Ulmer and Oliver Antons and Julia C. Arlinghaus},

url = {https://www.ms.ovgu.de/Research/Data.html

https://www.ms.ovgu.de/ms_media/Downloads/Data_Dynamic_Multi_Period_Recycling_Collection_Routing-p-604.zip

https://rdcu.be/d9abe

},

doi = {10.1007/s00291-025-00808-z},

issn = {1436-6304},

year = {2025},

date = {2025-02-08},

urldate = {2025-02-08},

journal = {OR Spectrum},

publisher = {Springer Science and Business Media LLC},

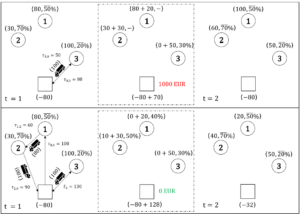

abstract = {We consider the problem of collecting and processing waste material. At a production facility, a known amount of inventory is required for production (e.g., paper) for every period. Instead of new material, the facility relies on collected and processed waste material (e.g., paper waste). This material is collected from regional waste collection locations. The amount of waste material per location is uncertain, as is the quality of the collected waste, i.e., the resulting inventory when processing the material. If the inventory is insufficient at the end of a period, costly new material must be bought. Each period, decisions are made about how much waste material to collect from which location and how to route the collection vehicles accordingly. Ideally, inventory is built to hedge against quality uncertainty and to ensure efficient routing operations in future periods. We propose a stochastic lookahead method that samples a set of scenarios and solves a simplified two-stage stochastic program in every period. We show the value of our method for two case studies, one based on real-world data from Sachsen-Anhalt, Germany, and one from the literature with data from the United Kingdom. We further conduct a detailed analysis of our method and the problem characteristics. The results show that our method effectively anticipates all sources of uncertainty, reducing cost significantly compared to benchmark policies. This superior performance is due to appropriate state-dependent supplier selection that considers the percentage of material loss, available material, and routing cost for current and future periods.},

keywords = {Benchmarking, Buyer-Supplier Relationship, Circular Economy, Circular Supply Chain, Decision-making, Linear programming, Optimization, Sustainability},

pubstate = {published},

tppubtype = {article}

}

2023

Oliver Antons; Tobias Benecke; Sanaz Mostaghim; Julia C. Arlinghaus

Sustainability in Chemical Production–Multi-Objective Distributed Control Book Section

In: New Trends in Intelligent Software Methodologies, Tools and Techniques, pp. 211–219, IOS Press, 2023.

Abstract | Links | BibTeX | Tags: Chemical industry, Circular Economy, Distributed control, Optimization, Sustainability

@incollection{antons2023sustainability,

title = {Sustainability in Chemical Production\textendashMulti-Objective Distributed Control},

author = {Oliver Antons and Tobias Benecke and Sanaz Mostaghim and Julia C. Arlinghaus},

doi = {10.3233/FAIA230236},

year = {2023},

date = {2023-01-01},

urldate = {2023-01-01},

booktitle = {New Trends in Intelligent Software Methodologies, Tools and Techniques},

pages = {211\textendash219},

publisher = {IOS Press},

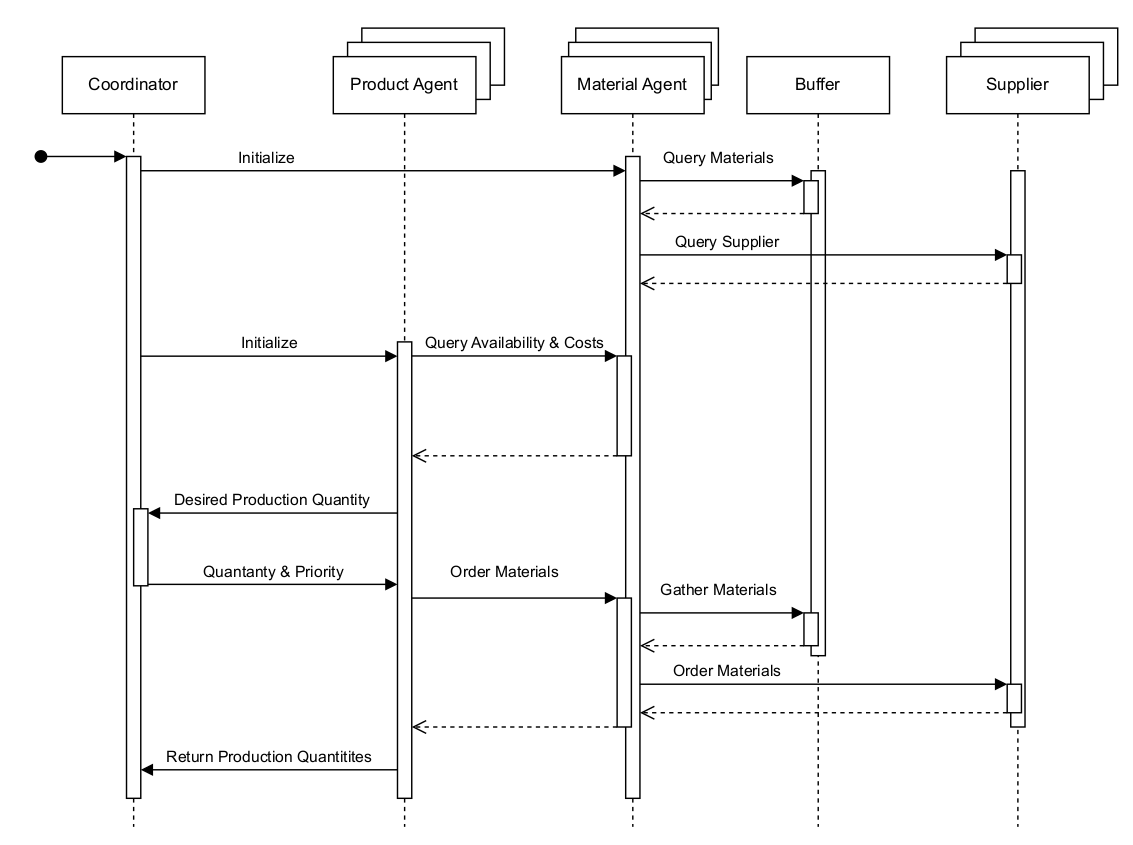

abstract = {Chemical industry provides a multitude of intermediaries and final products essential to society, ranging from fertilizers and plastics to sophisticated pharmaceuticals. The underlying production processes are typically linear, utilizing finite resources in an unsustainable manner and creating unnecessary waste over a products lifetime. While a shift towards sustainability and circular economy is desired, the current market and political framework lead to conflicting objectives ranging from sustainability to profit maximization. In this article, we build upon a first minimal multi-objective MILP model and extend thereupon, reducing the overall level of required abstraction compared to the first model. Thereafter, we present a multi-agent based distributed optimization approach for a sequence of the extended MILP formulation.},

keywords = {Chemical industry, Circular Economy, Distributed control, Optimization, Sustainability},

pubstate = {published},

tppubtype = {incollection}

}

2022

Oliver Antons; Julia C. Arlinghaus

A Manufacturing Scheduling Complexity Framework and Agent-Based Comparison of Centralized and Distributed Control Approaches Journal Article

In: IEEE Journal of Emerging and Selected Topics in Industrial Electronics, vol. 3, no. 1, pp. 31-38, 2022.

Abstract | Links | BibTeX | Tags: Autonomy & Decision-making Authority, Complexity Theory, Decentralized Control, Job-shop scheduling, Manufacturing, Optimization, Production

@article{antons2021ieee,

title = {A Manufacturing Scheduling Complexity Framework and Agent-Based Comparison of Centralized and Distributed Control Approaches},

author = {Oliver Antons and Julia C. Arlinghaus},

url = {https://doi.org/10.1109/JESTIE.2021.3100272},

doi = {10.1109/JESTIE.2021.3100272},

year = {2022},

date = {2022-01-01},

urldate = {2022-01-01},

journal = {IEEE Journal of Emerging and Selected Topics in Industrial Electronics},

volume = {3},

number = {1},

pages = {31-38},

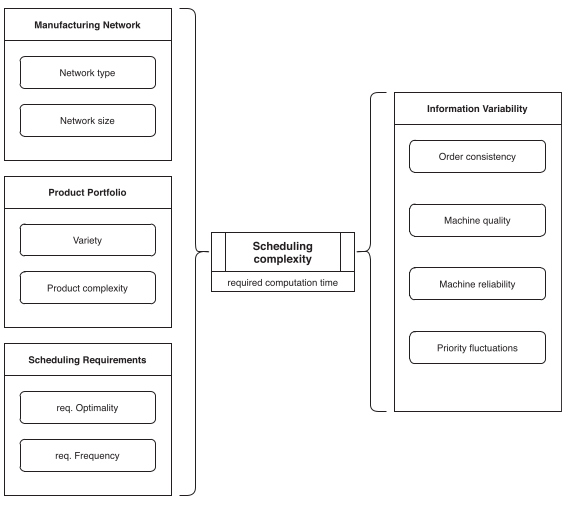

abstract = {Centralized approaches are often employed to control manufacturing networks in practice. The introduction of industrial cyber-physical systems driven by advances in microcontroller, sensor, and networking technologies is providing distributed control systems with the technical requirements needed to mitigate the drawbacks of centralized control, such as long optimization times that result in long planning horizons and inflexibility. While such distributed control approaches respond to the growing challenges faced by industry in terms of flexibility, resilience, and lot sizes, the inherent myopia of autonomous agents may discourage practical application. In this article, we develop a scheduling complexity framework derived from the literature, which allows researchers and prationers alike to evaluate the suitability of both centralized and distributed control approaches for manufacturing planning and control. This framework utilizes quantifiable environment variables, which influence we study by means of a multiagent discrete event simulation.},

keywords = {Autonomy \& Decision-making Authority, Complexity Theory, Decentralized Control, Job-shop scheduling, Manufacturing, Optimization, Production},

pubstate = {published},

tppubtype = {article}

}